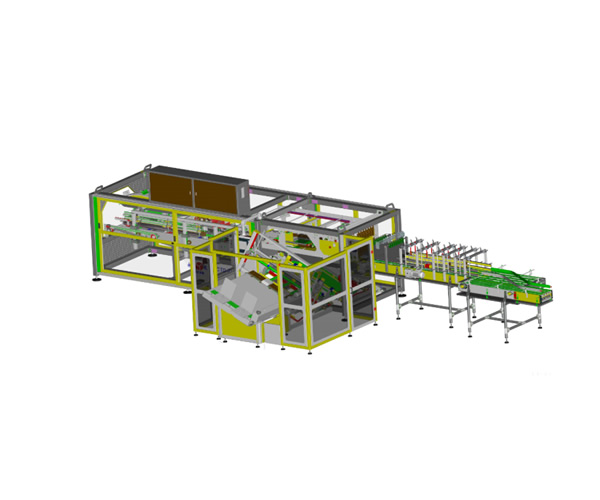

YCL35 and 40 and 50 series wrap-around carton packing machines are suitable for carton packaging of bottled (canned) production lines for bottling water, beer, beverages, food, etc. The cardboard packing method saves about 1/5 of the cost of packaging materials compared to the traditional packing method.

The combination of centralized system and touching screen improves various control functions of packaging, and directly input, modify and store parameters of various packaging specifications.

The flat cardboard is used for one-time forming and wrapping, and the unique box pressing technology enables the carton to be formed more firmly, the packaging effect is good, the labor intensity of the operator is greatly reduced, and the requirements for the cardboard are also greatly reduced.

Using well-known hot melt adhesive equipment, easy to operate and durable. The product packaged has a neat appearance, beautiful appearance and convenient storage and transportation. The slim body design saves space, beautiful and safely. Capacity is about 20 to 45 cases/min. 4 x 6/500ml..

Technical features:

1. The mechanical parts are made of stainless steel, carbon steel, chrome-plated steel and aluminum alloy with strong corrosion resistance. Equipped with installation of protective doors.

2. Manual stand-up cardboard loading structure, adapting to ergonomic principles; large-capacity cardboard bin, up to 500 cardboards; cardboards are separated step by step, and a more stable rubbing structure is used when a single cardboard is separated, with stable and reliable performance and high efficiency.

3. With Schneider touch screen operation, parameters can be adjusted on the man-machine interface, which is easy to adjust, and can display the production speed, fault cause and location, highly automation.

4. Adopt Schneider PLC and Schneider frequency converter to realize precise position control, and have fast communication capability and powerful diagnostic function to ensure the reliability of the system. The operation is convenient, the structure is compact and reasonable, and highly automation.

5. Most of the electrical components are well-known European brands with stable performance and high efficiency.